Why Injection Molding is Essential for Mass Production

Introduction In the realm of mass production, efficiency and cost-effectiveness are paramount. Industries worldwide strive for manufacturing...

1 min read

Nick Erickson : Jan 24, 2025 11:40:11 AM

.webp?width=900&height=900&name=QTT%20guide%20Image%20(1).webp)

When speed, cost, and precision are critical in the prototyping process, quick turn tooling offers an ideal solution. Leveraging modular systems like MUD (Master Unit Die) sets, manufacturers can achieve faster turnaround times and reduce costs while maintaining the quality needed for short production runs or prototypes. Here's everything you need to know about this approach.

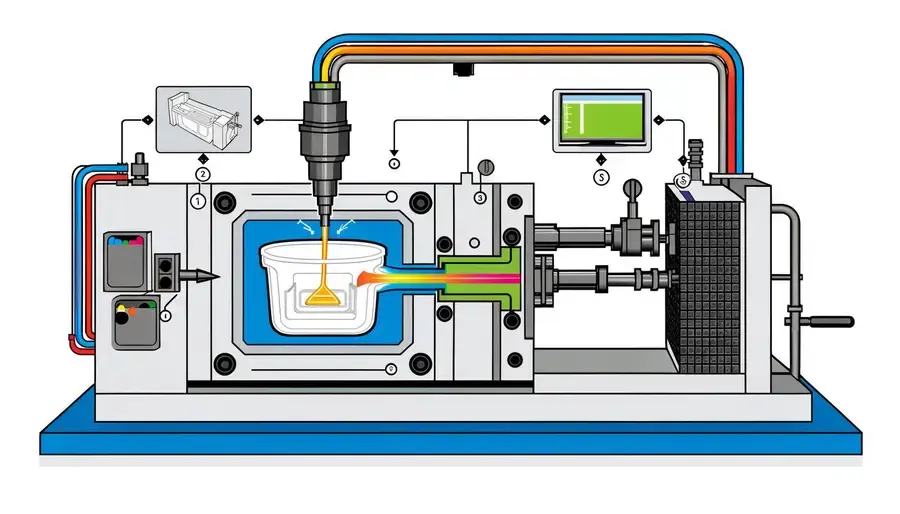

Quick turn tooling uses modular injection molding systems, such as MUD sets, to streamline the mold-making process. A MUD set works by integrating a smaller, interchangeable mold insert containing the unique cavity into a standard base that remains mounted in the molding machine. This setup significantly cuts down on lead times and tooling expenses compared to traditional injection molding methods.

Rapid Lead Times

Compared to general and specialized production tooling, quick turn tooling offers faster turnaround—typically within 3–5 weeks. This speed makes it particularly useful for prototyping and testing before moving to full-scale production.

Cost Efficiency

With costs starting around $15k, quick turn tooling is a cost-effective option for projects requiring up to 25,000 shots. By comparison, general production tooling and specialized production tooling often cost significantly more, starting above $15k and $25k, respectively.

Customizable Options

Quick turn tooling offers features like DFM (Design for Manufacturing) support, custom gate locations, and ejection methods provided by Aprios. The system accommodates simple to moderately complex designs and supports SPI-C3 surface finishes.

Compact Size

The maximum build box size for quick turn tooling is 3” x 3” x 3”, allowing for precise manufacturing of smaller components.

| Feature | Quick Turn Tooling | General Production | Specialized Production |

|---|---|---|---|

| Lead Time | 3–5 weeks | 4–8 weeks | 8–12 weeks |

| Cost | ~$15k | >$15k | >$25k |

| Tolerances | ±0.01 | ±0.005 | ±0.002 |

| Shots | 25k | 100k | 500k |

| Complexity | Simple–Moderate | Moderate–Complex | Complex–Extreme |

| Surface Finish | SPI-C3 | SPI-B2 | SPI-A22 |

| Cavitation | 1–2 (Upon Review) | 2–8 | 8+ |

Quick turn tooling is ideal for:

However, it has its limitations in terms of:

For more advanced requirements, such as higher cavitation or extreme design complexity, general or specialized production tooling may be a better fit.

Introduction In the realm of mass production, efficiency and cost-effectiveness are paramount. Industries worldwide strive for manufacturing...

Learn how to optimize mold design for efficient injection molding and improve product quality while reducing costs.

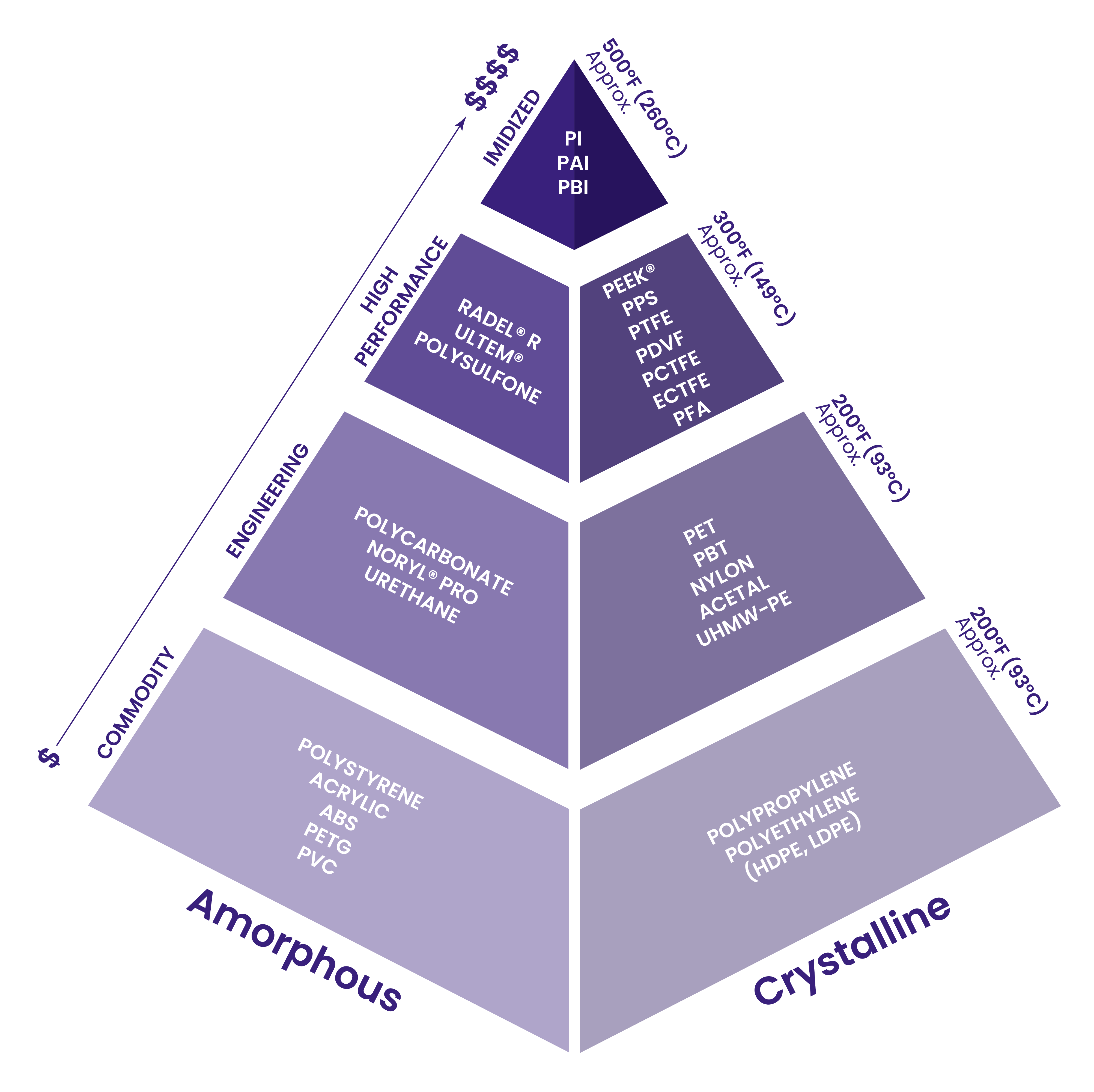

Choosing the Right Material for Injection Molding: A Comprehensive Guide Material selection is a critical aspect of injection molding, influencing...